About us

Coesin is a Sicilian company that designs and provides control and monitoring systems in the industrial automation sector. From the electronic and electrical service on machines and manufacturing lines, to the empowerment of integrated systems by developing a package of management application software. The know-how acquired over fifteen years of experience on the field, together with the professionalism and the flexibility of our technicians, make us able to handle and coordinate multidisciplinary and demanding projects.

We do provide turnkey projects working on every phase of their process. Starting from designing to the final delivery and including post-selling assistance of process plants and advanced smart manufacturing systems as industry 4.0.

As system integrator, Coesin is a company with a wide cross-section of customers on the target market: manufacturing, processing and packaging companies coming from different industrial sectors such as agrifood, metalworking-mechanical engineering and manufacturing.

Scada software development PLC and HMI software design Technical service on production lines and CNC System Integrator: Robotics, Vision Inspection Systems, IoT, building automation Remote and Predictive Maintenance

Our Mission

Coesin operates side by side with customers to guarantee the most productive plant efficiency and deliver custom and modular solutions. Always looking for performance improvements in order to decrease both the costs and the downtime.

Our Vision

We are dreaming of a future in which many Sicilian companies could bring on the table their dynamic and sustainable production and promote Sicily as a big brand all over the world.

Our history

Born from a well established experience of five partners on the field, the company has deep knowledge of the market needs. Coesin operates to supply custom and modular solutions for industrial plants and machines. We are a Start-up with an innovative patent providing a smart and integrated system of activation and control on industrial buildings and agricultural hothouses.

Coesin was founded in 2016 out of the bravery of five former colleagues who decided to boost on their entrepreneurial spirit, putting an effort not to quit their land and spreading out their acquired know-how. This in order to stay and invest their resources on the territory. The name Coesin was chosen on purpose: it indicates a work ethic. And those shared values in which we identify ourselves. Values like professionalism, responsibility and expertise at the service of customers.

Our Team

We are a qualified and well-tight team working closely with customers in order to fulfill their needs.

We strive constantly to find the most advanced solutions for a better efficiency in terms of energy and financial savings. With the goal of reducing the costs and the turnaround time of the plants.

Awards

Our services

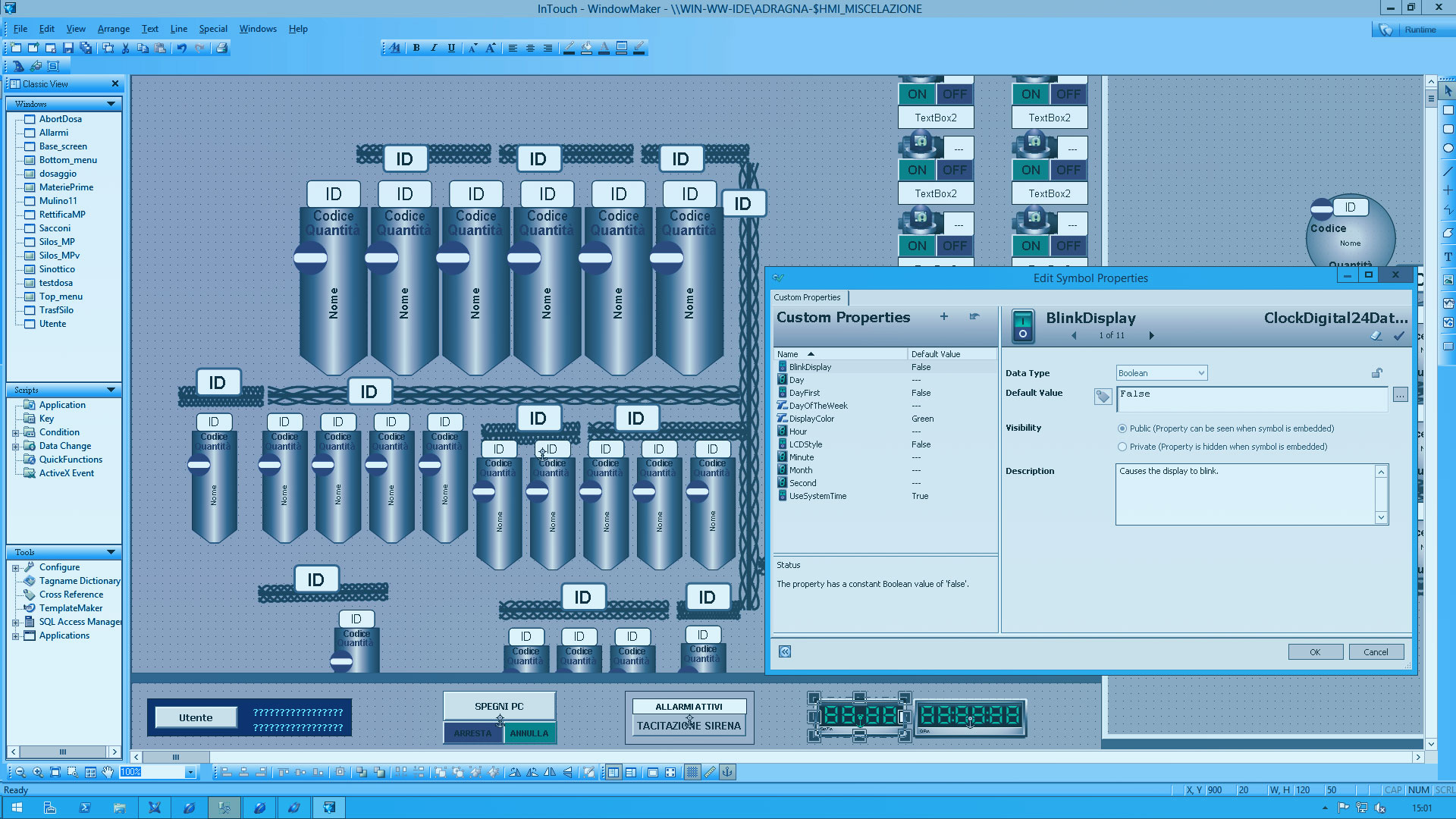

PLC and SCADA software design

The company has gathered considerable and qualified experience on a wide range of software control systems, from the development of applications on the most important controllers, to plants process and monitoring analysis on the most important Scada.

PLC and HMI programming

Expert on HMI software development and PLC programming for plants monitoring and control.

The HMI software can be optimized on different hardware devices: from touch panels till industrial PCs.

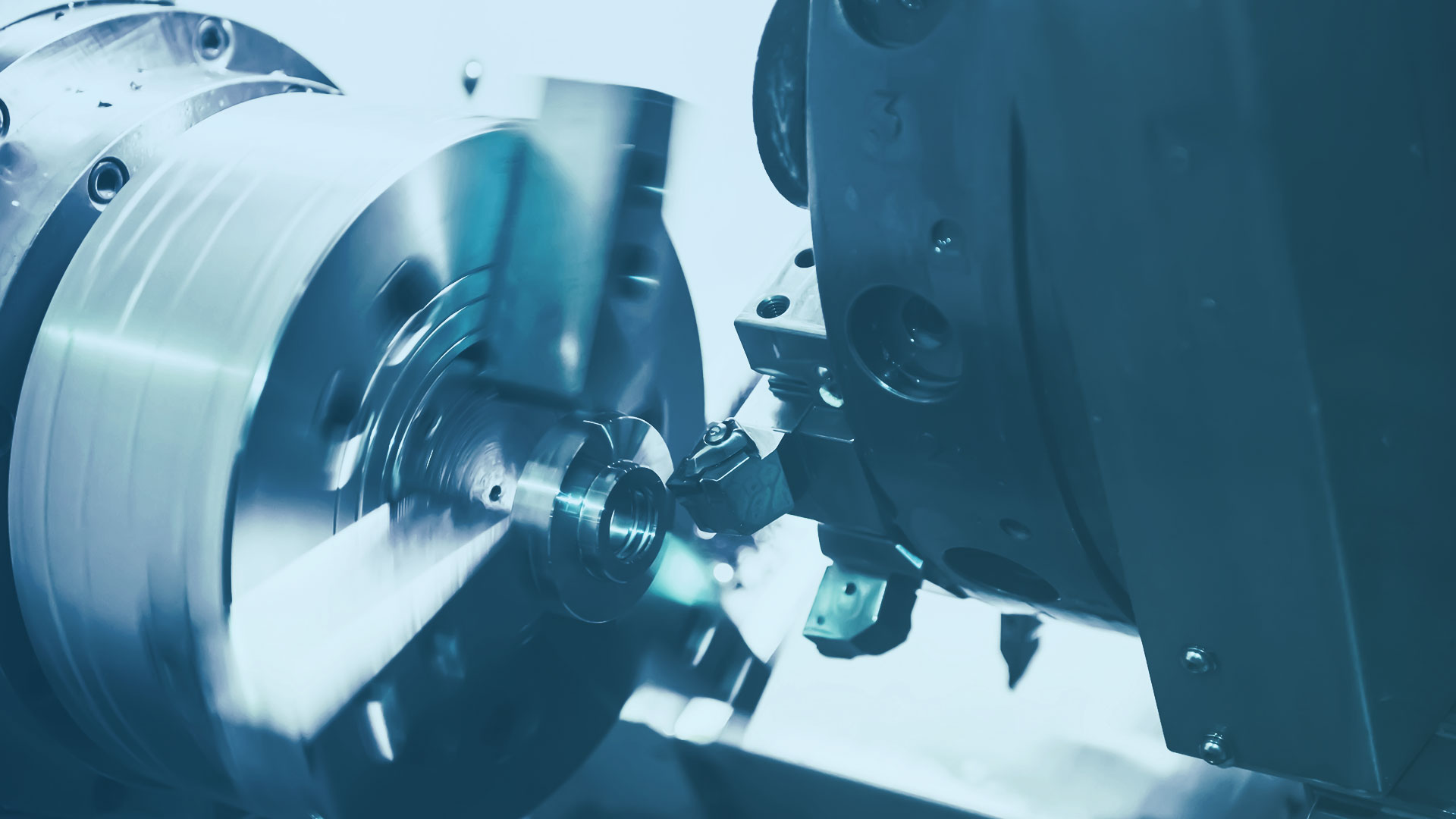

Revamping

We have gathered a strong experience on obsolete industrial machines revamping service with the update of PLC and numeric control.

Service on CNCs and machines

Aware of the the importance of efficient and functional machines for the companies, we offer a high standard and fast technical service with specialised technicians making rapis interventions reducing the turnaround time of machines.

Vision inspection system for quality control

Coesin supplies turnkey solutions for integrated systems on quality control and traceability.

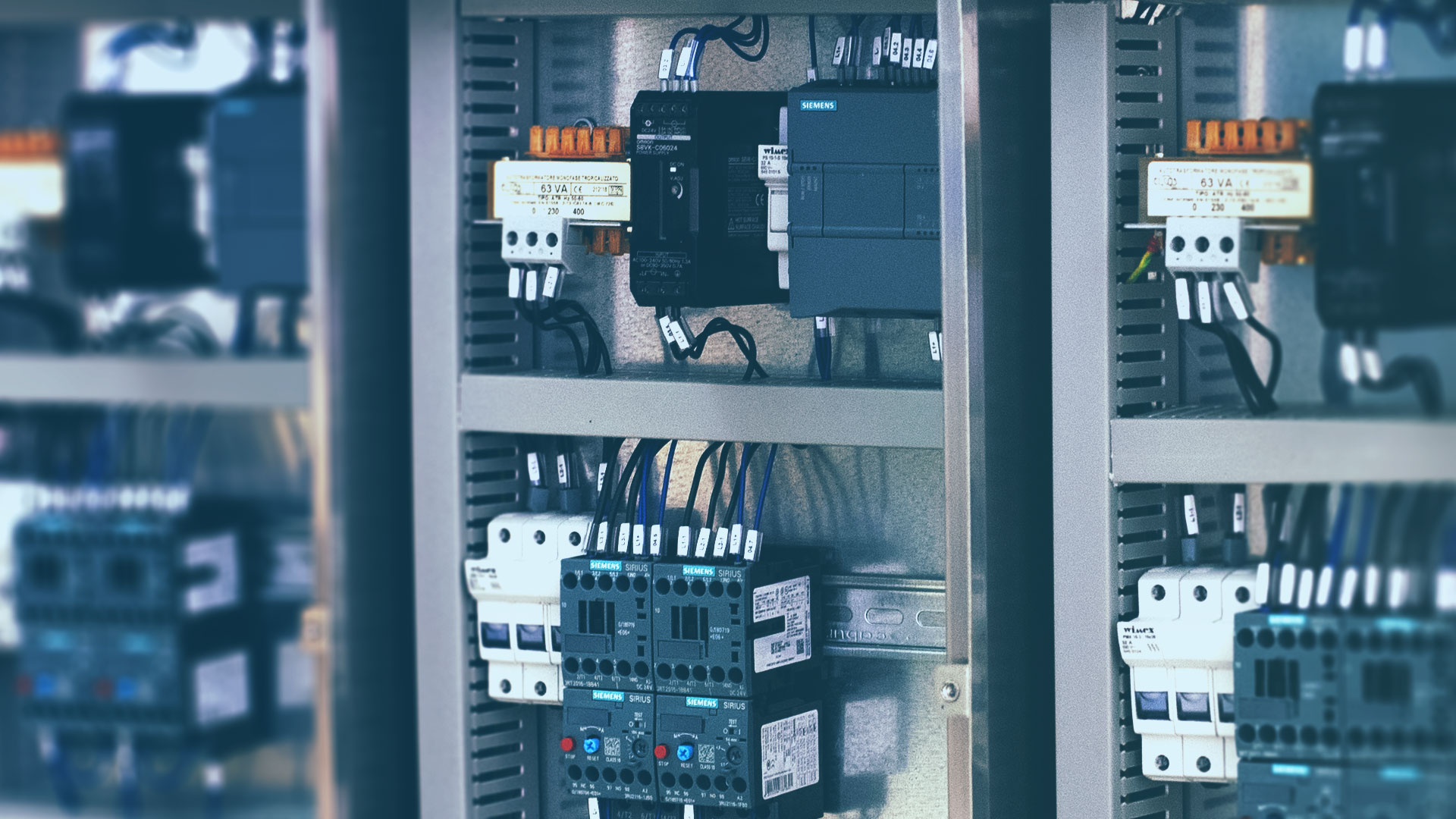

Automation plants design and delivery.

Experts on control panels designing and delivering by using dedicated softwares for PLCs and on-board machine system.

Remote Maintenance

In order to guarantee rapid interventions, the remote technical service allows our technicians to operate on industrial plants, systems and machineries directly from our office, ensuring an operative and on line support and lowering the turnaround times. If the remote technical service package cuts on-site technical interventions costs, it also allows to diagnose faults and problems from remote and to intervene at the customer’s site fully prepared and informed.

Predictive Maintenance

The predictive maintenance, together with the Industry 4.0 tools, allows to collect immediate pieces of information on the productive process within a company, through smart devices that acquire and communicate data to other devices, working together in close sinergy. The data are then interpreted from a model that will indicate if the machine needs the maintenance service.